Reducing the carbon footprint in asphalt

Recycled asphalt

The simplest way to reduce the carbon footprint of asphalt is to use recycled asphalt in the production of asphalt mixtures (made from asphalt waste, milling debris, etc.). As of March 2025, regulations in Estonia allow the use of recycled asphalt up to 30% of the mixture’s total weight. A high-quality end result is ensured through careful sorting of asphalt waste and thoughtful layer-by-layer milling on construction sites, which makes it possible to use recycled asphalt in virtually every layer, depending on the quality indicators of the recycled asphalt obtained.

MacRebur MR8

Another additional option is to use the MacRebur MR8 additive, which replaces a portion of the bitumen added to the mixture. MacRebur MR8 is a special additive for asphalt made from recycled plastic waste (such as insulation materials from electrical cables). The MacRebur MR8 additive helps reduce the use of traditional materials in the asphalt industry and has strong potential to mitigate the environmental impact of road construction.

Lignin-based asphalt mix

Another option for partially replacing bitumen is to use lignin. Lignin is a biopolymer produced during the refining of wood, which can be used to partially replace bitumen in the mixture. In 2022, Tariston produced the first lignin-containing asphalt mixtures in Estonia. In 2024, at the request of the Estonian Road Administration, we set up the first test sections covered with lignin-based asphalt on a public highway during the reconstruction of the Koeru-Kapu section of State Road No. 25 between Mäeküla-Koeru-Kapu.

Infrastructure innovation

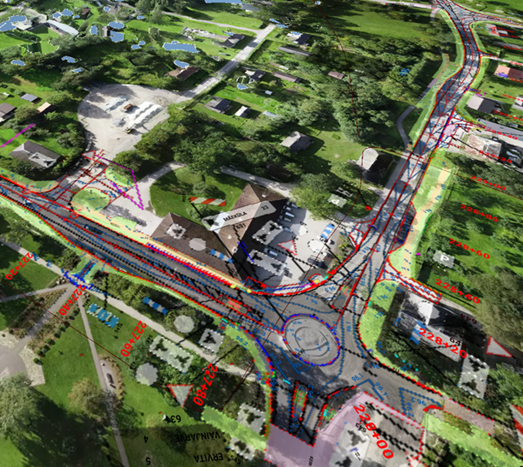

3D machine control and BIM in road construction projects

Tariston AS has been using 3D machine control technology in its road construction projects since 2013 to increase work efficiency and reduce the need for traditional surveying.

On behalf of the Transport Administration, AS Tariston has carried out several different pilot projects, where the aim has been to use modern machine control and surveying technology in the construction, and in such a way that in addition to increasing work productivity, it would be possible to use machine control equipment also to perform surveys necessary for the acceptance of work.

Such objects have been in:

- 2020 at secondary road 15160 Köisi-Koigi km 0-8.768;

- 2023, reconstruction of the secondary road 15212 Raukla – Äiamaa – Oisu km 0.046-2.760 and the secondary road 15173 Oisu – Kärevere – Taikse km 4.920-7.706,

- 2024, reconstruction of the Koeru-Kapu section of State Road 25 Mäeküla–Koeru–Kapu km 21.25-25.30.

First-of-its-kind solutions in Estonia

AS Tariston has built various test sections and built unique objects in all kinds of conditions. Swamps, bogs, or unexploded ordnance have not been an obstacle. We have always found a solution. For example, in 2021, for the first time in Estonia, we used tire blocks in the substructure of a road on a section of at least 3 kilometers long, commissioned by the Estonian Centre for Defence Investments. We have installed concrete mattresses on the Jäbi River, built a road on a training ground with unexploded ordnance, built Estonia’s first tankodrome, and done many other exciting things.